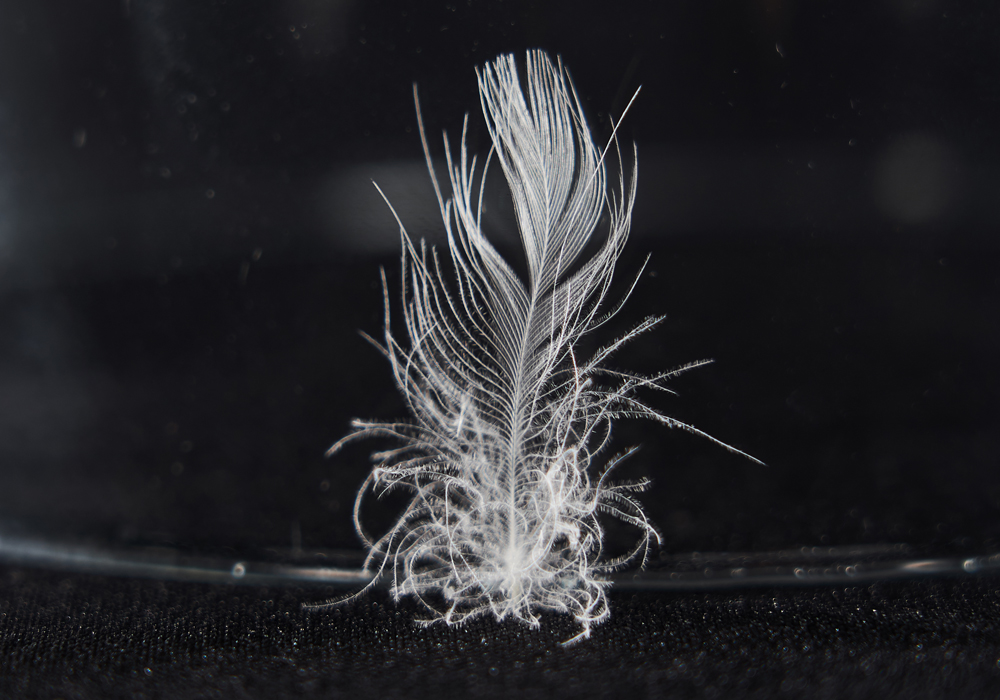

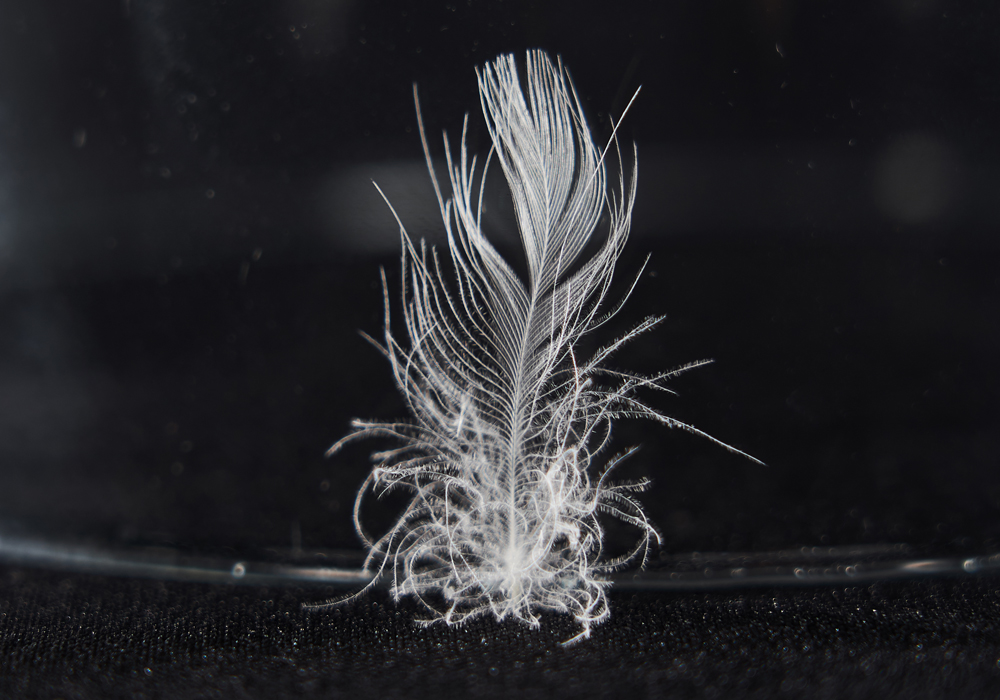

1.DOWN

SPECSThere are several specifications that describe the quality of down. Unfortunately, there is a lot of misapprehension around them, which is why we present an organized set of down specifications. In this presentation you will learn what down fill power is and what is the difference between CUIN and FP units, the difference between duck and goose down, down-to-feather ratio, and how different types of down are collected. |